An introduction to the lost wax casting process.

Lost wax casting, also known as investment casting or precision casting, is a manufacturing process in which a wax pattern is used to shape a disposable ceramic mold. A wax pattern is made in the exact shape of the item to be cast. This pattern is coated with a refractory ceramic material. Once the ceramic material is hardened, it is turned upside-down and heated until the wax melts and drains out. The hardened ceramic shell becomes an expendable investment mold. Molten metal is poured into the mold and is left to cool. The metal casting is then broken from of the spent mold.

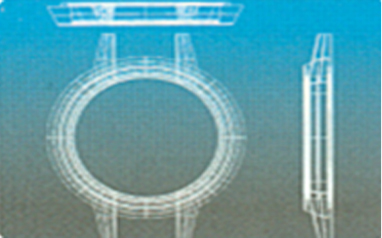

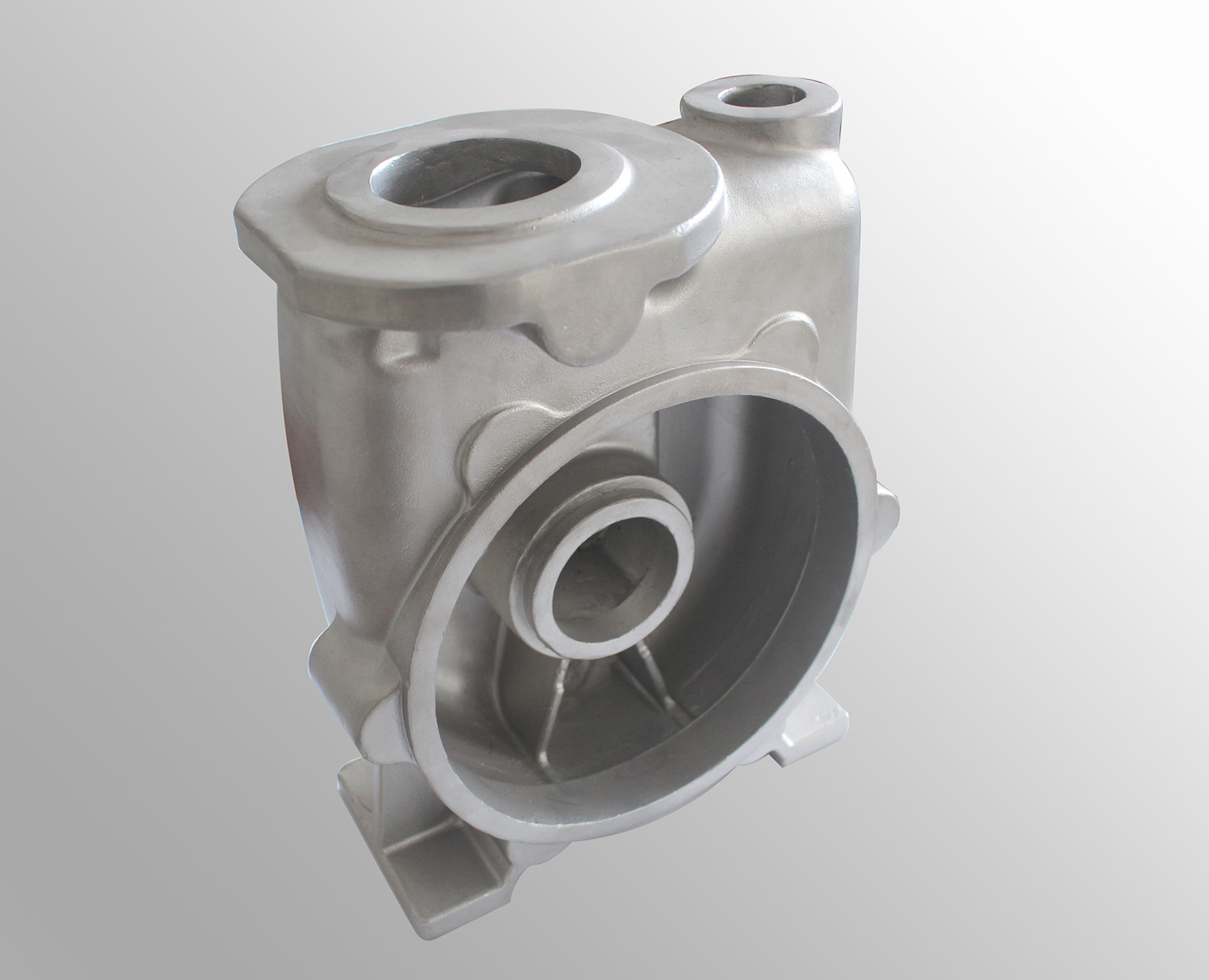

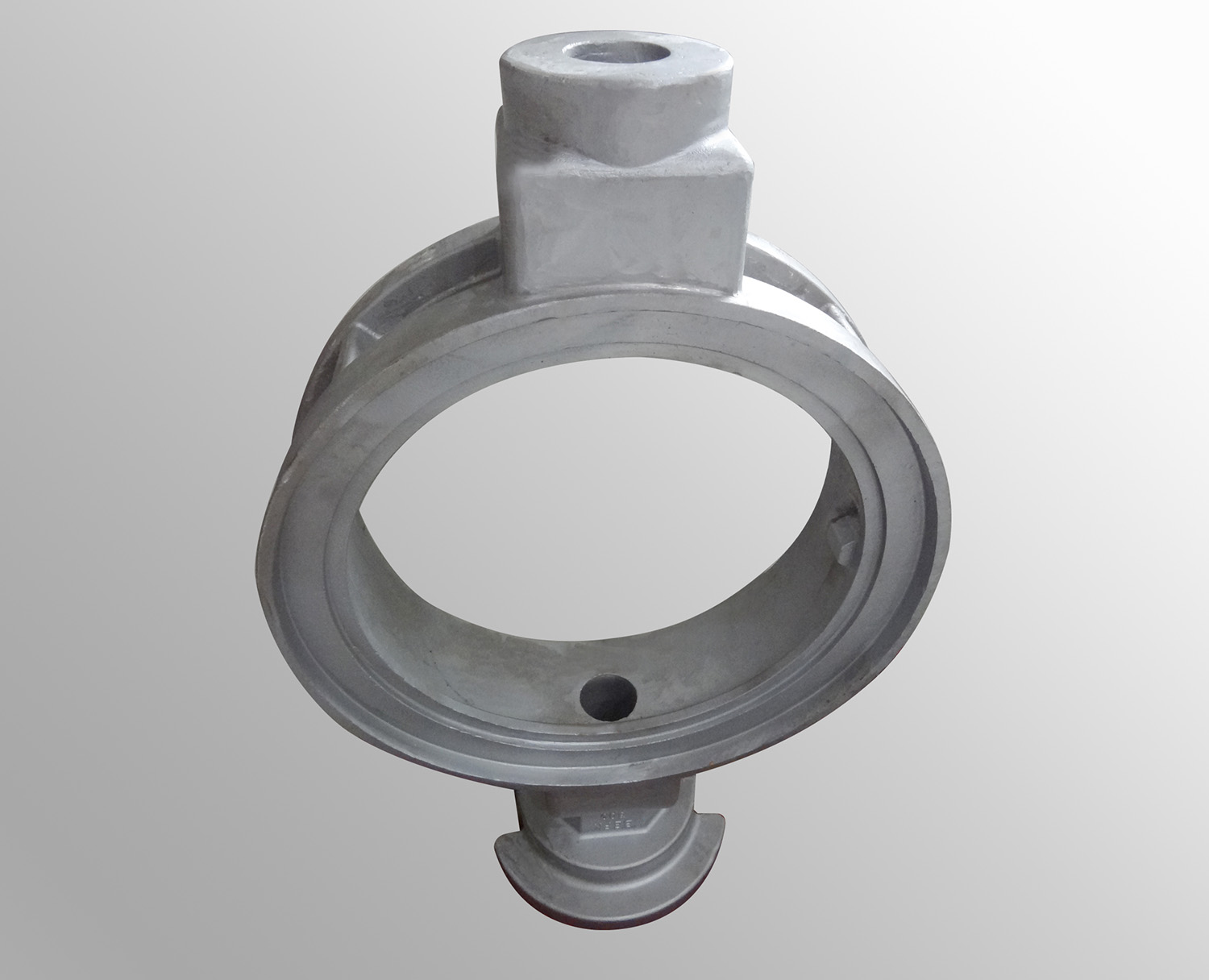

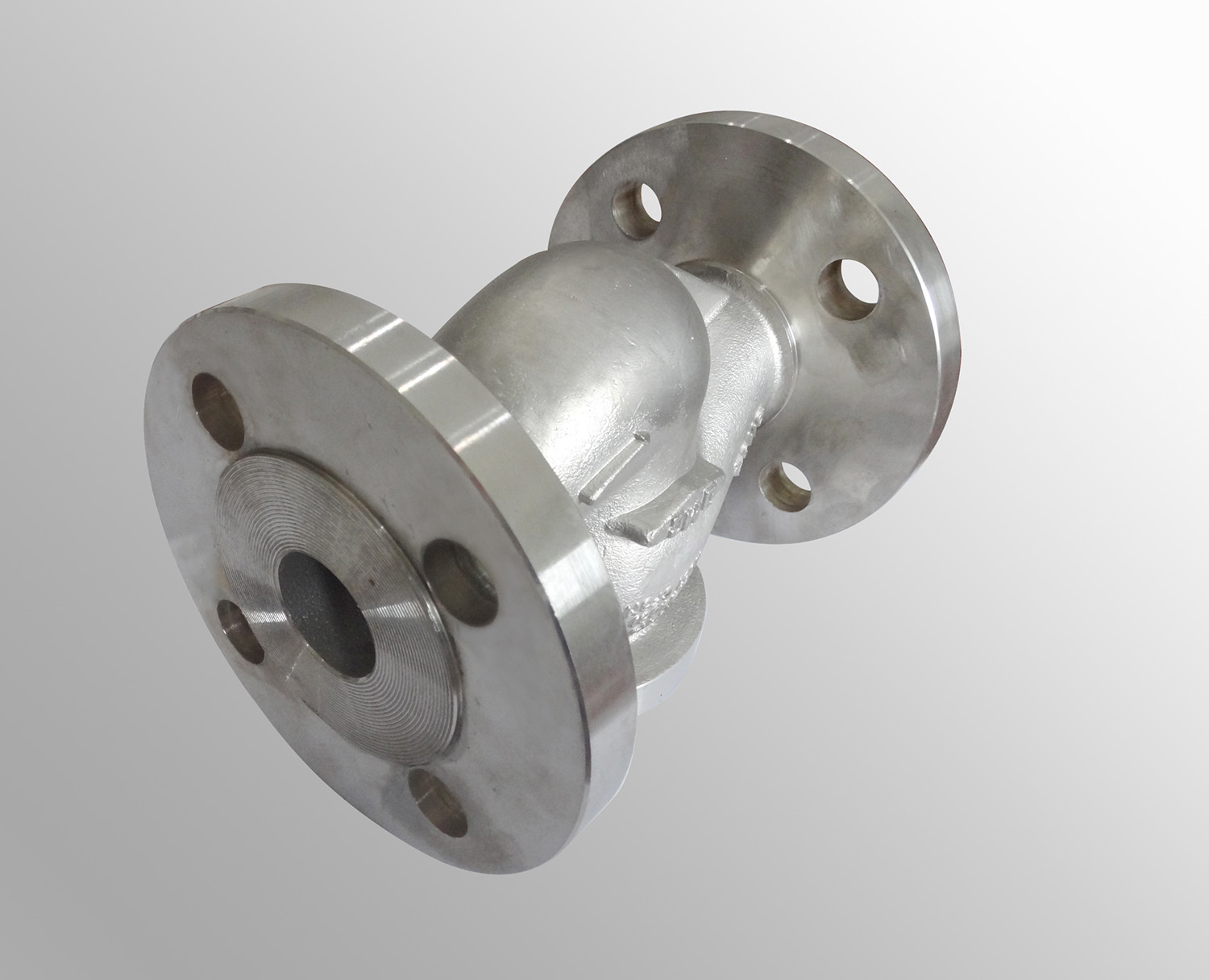

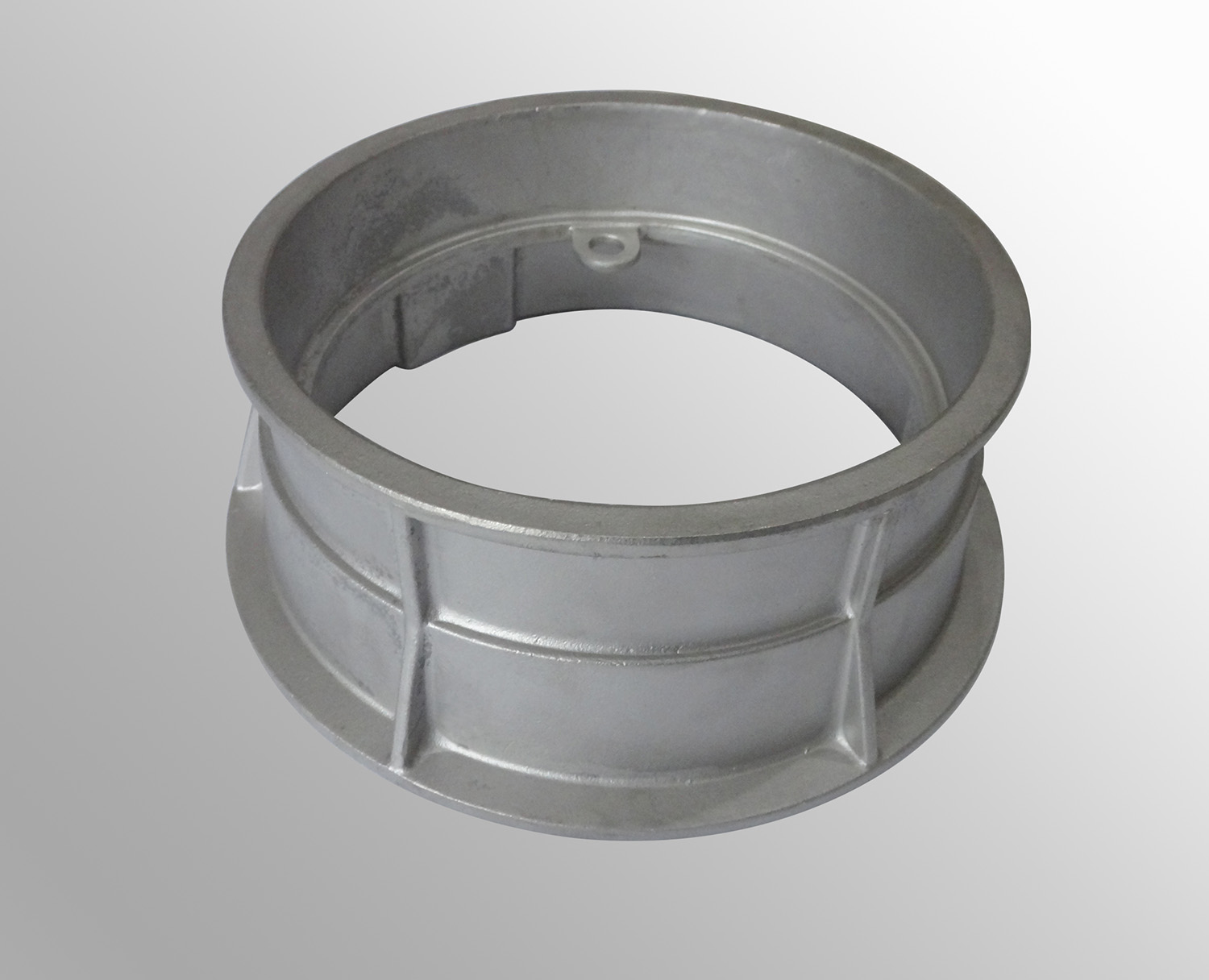

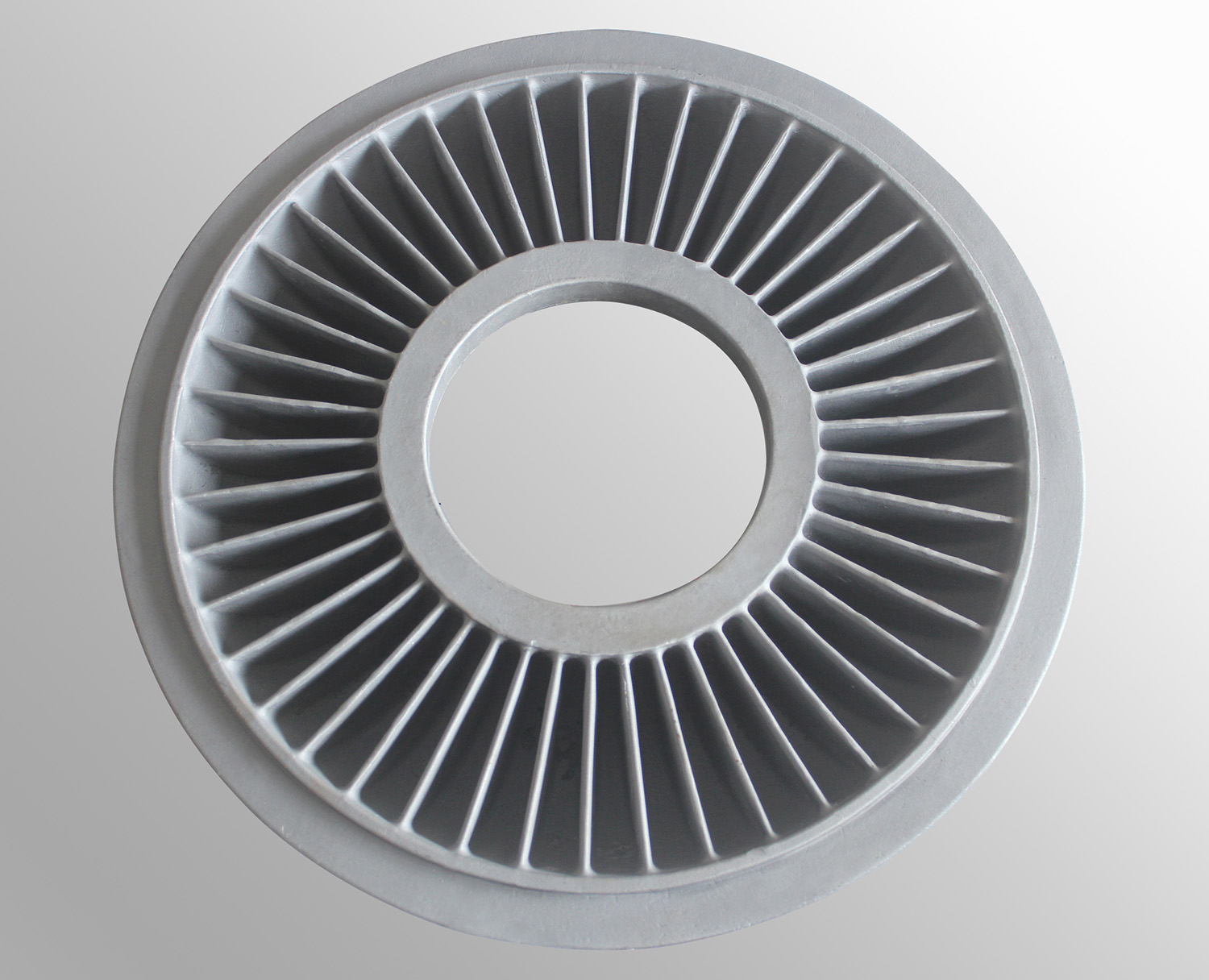

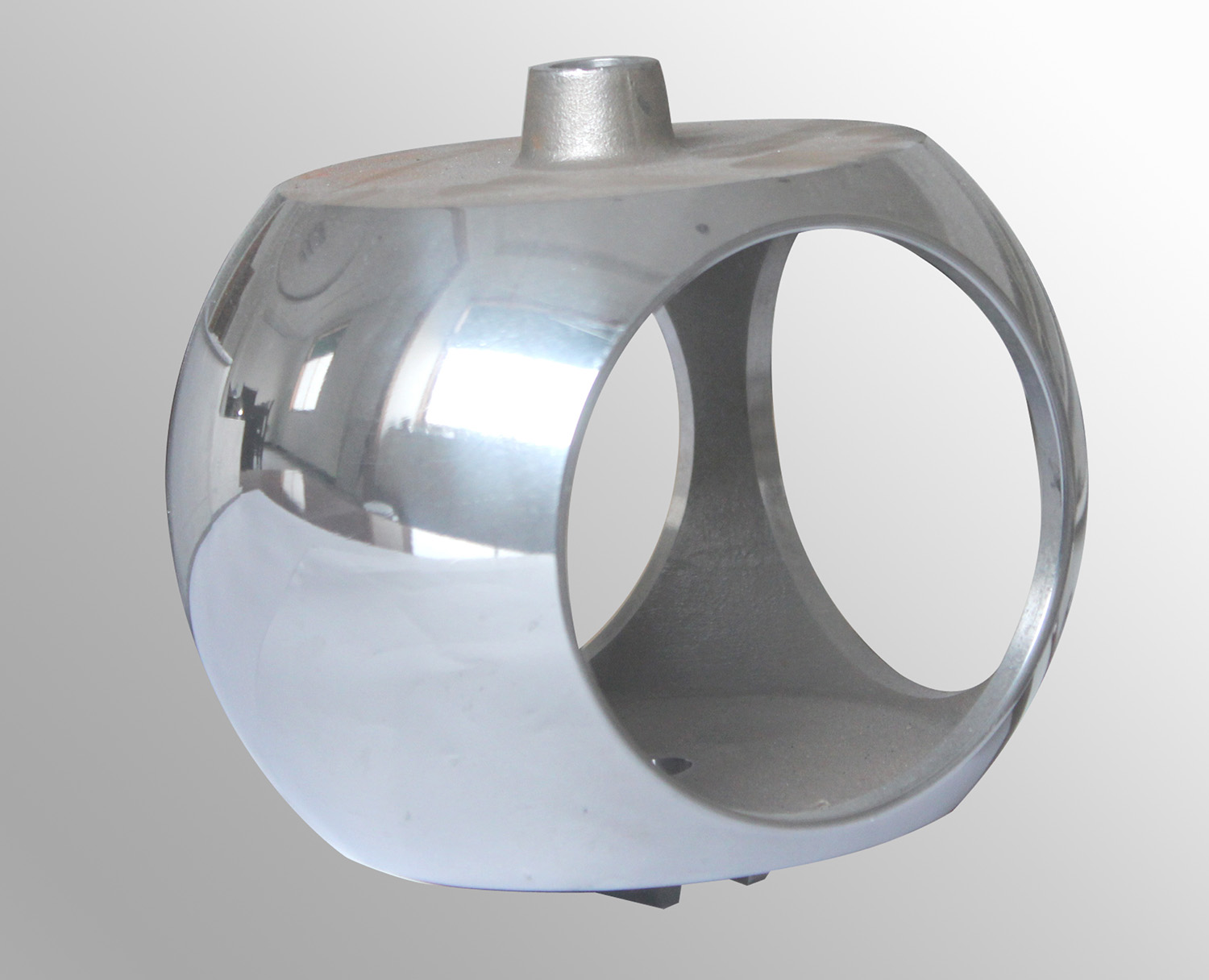

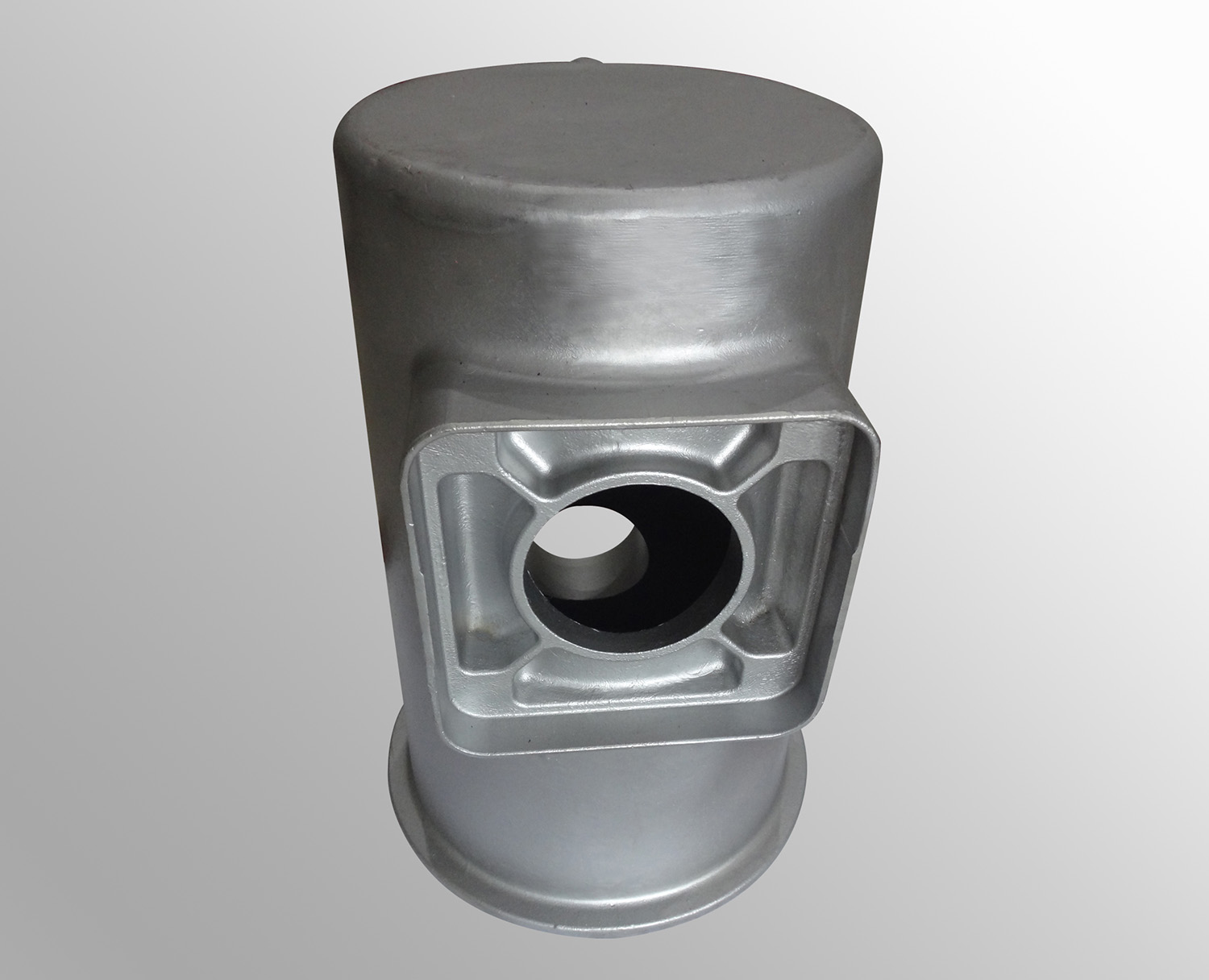

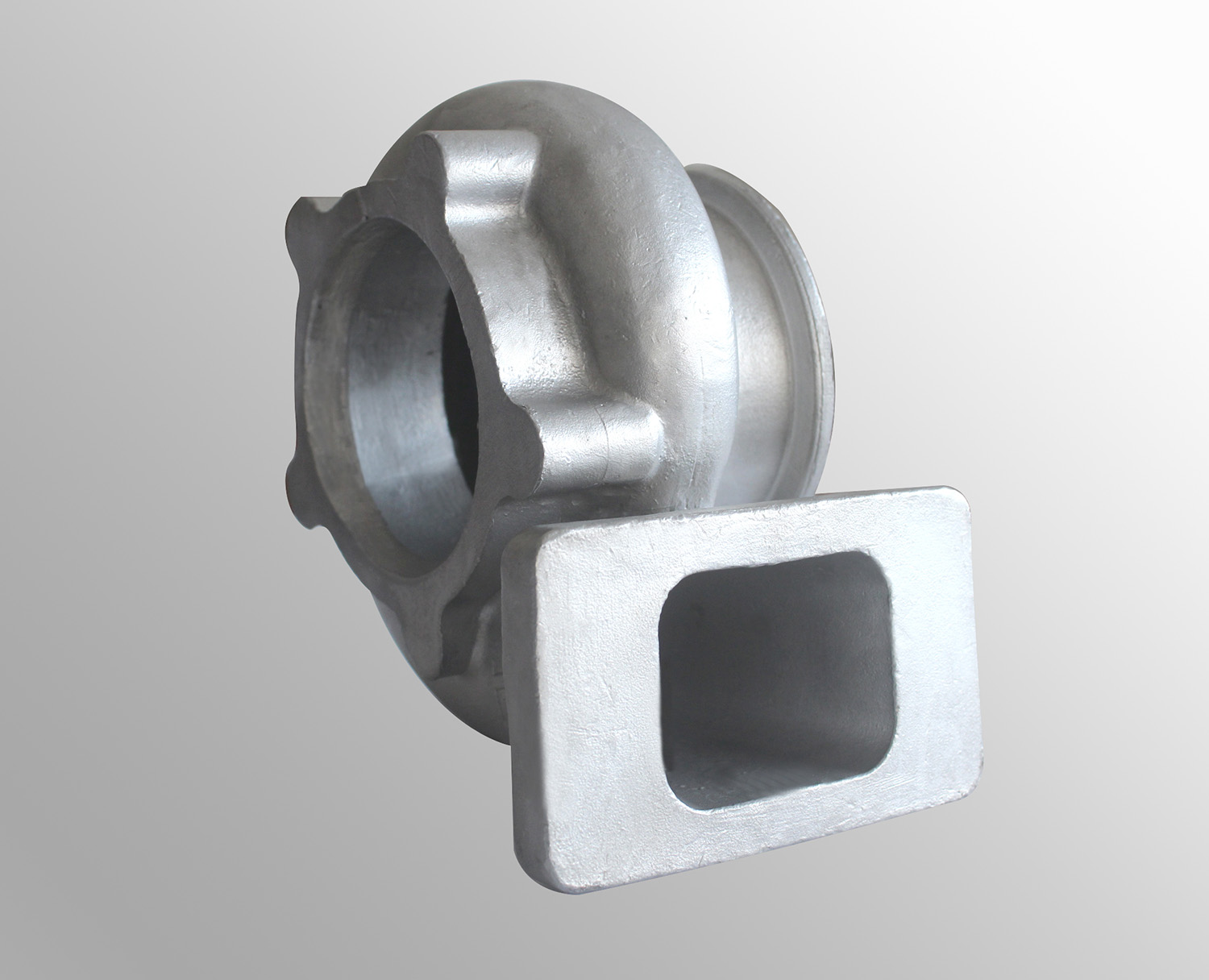

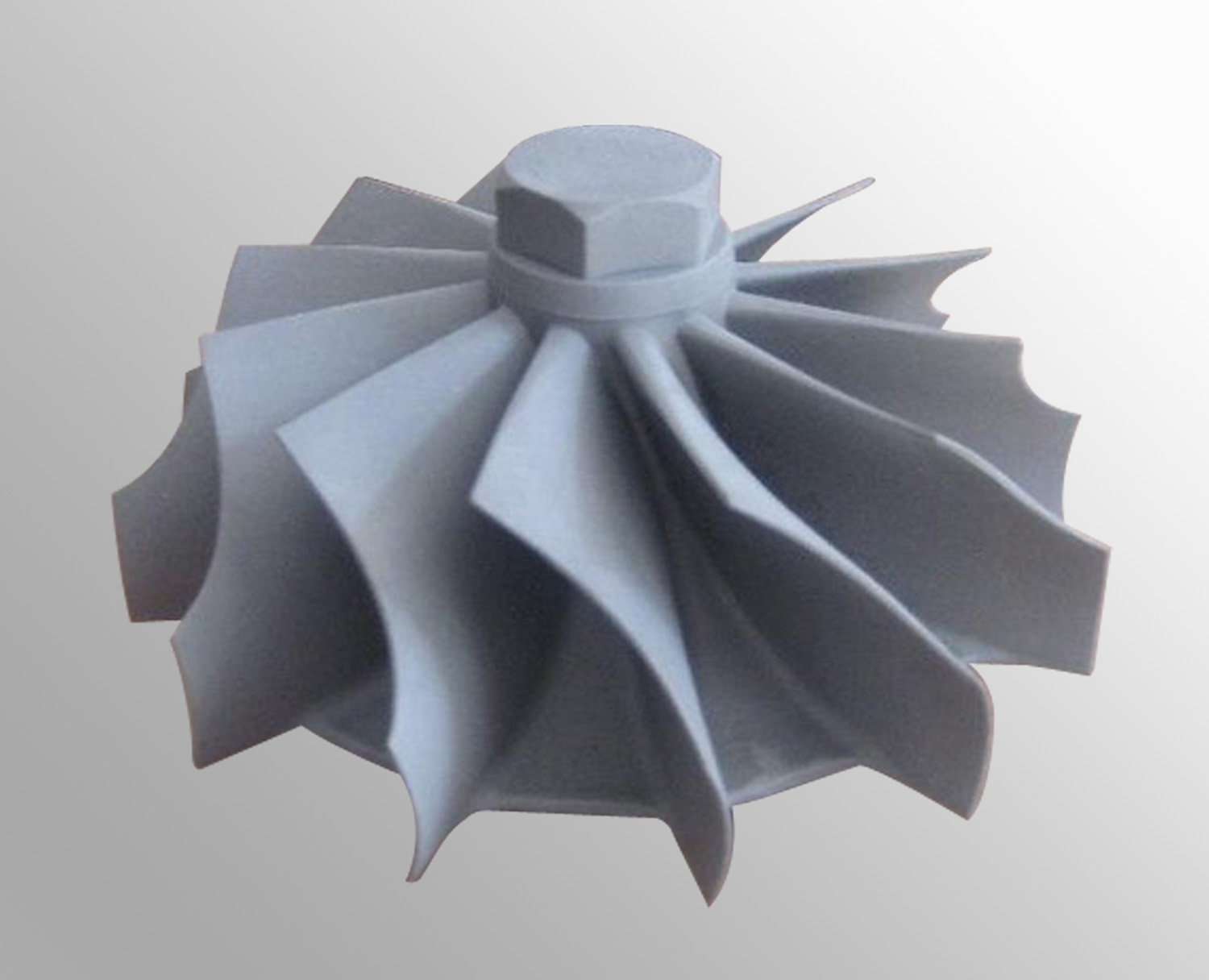

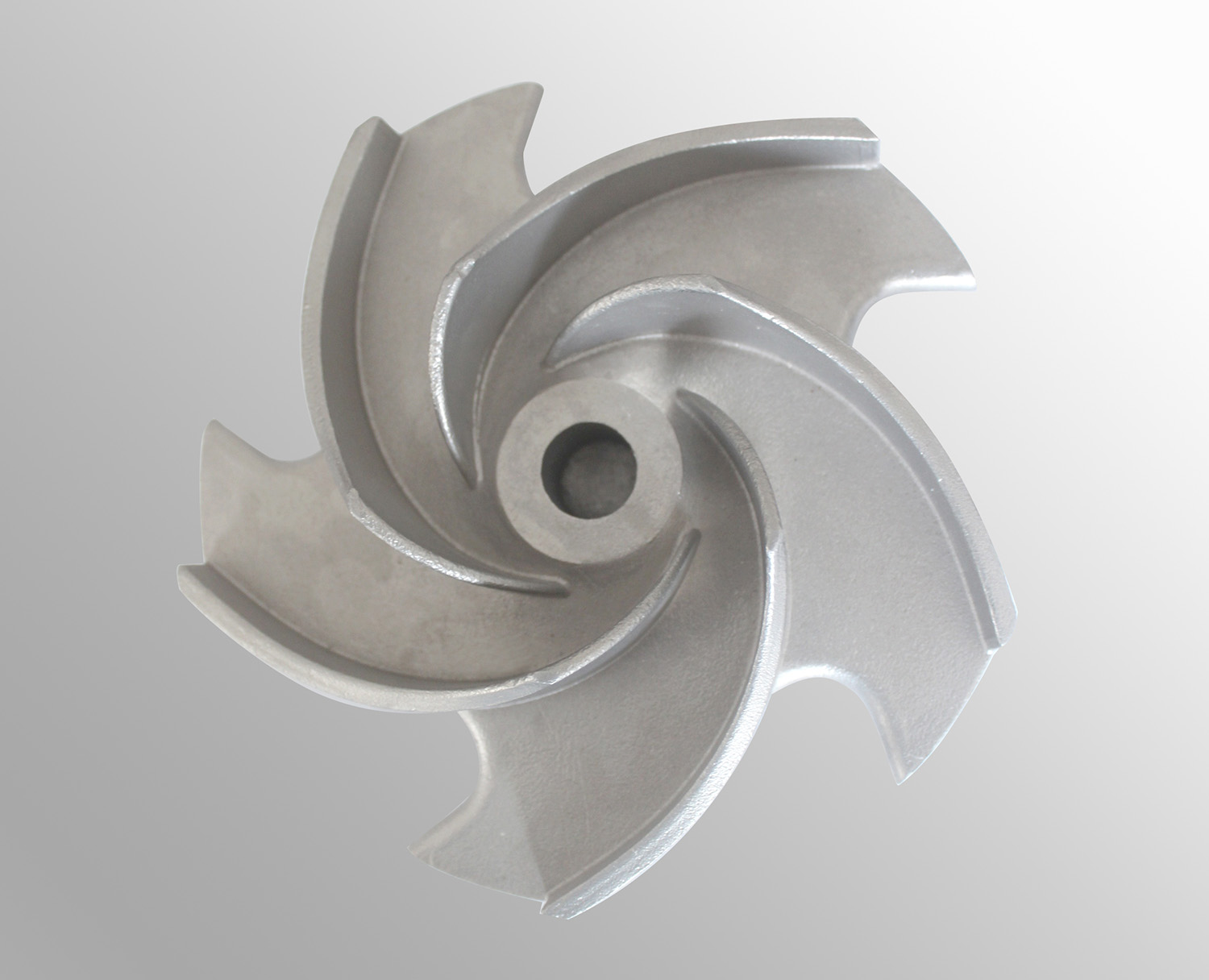

The term investment casting is derived from the process of “investing” (surrounding) a pattern with refractory materials. Investment casting is often selected over other molding methods because the resulting castings present fine detail and excellent as-cast surface finishes. They can also be cast with thin walls and complex internal passageways. Unlike sand casting, investment casting does not require a draft.

The wax pattern and ceramic mold are destroyed during the investment casting process, so each casting requires a new wax pattern. Unless investment casting is being used to produce a very small volume (as is common for artistic work or original jewelry), a mold or die from which to manufacture the wax patterns is needed.

The size of the master die must be carefully calculated; it must take into consideration expected shrinkage of the wax pattern, the expected shrinkage of the ceramic material invested over the wax pattern, and the expected shrinkage of the metal casting itself.

The number of wax patterns always equals the number of castings to be produced; each individual casting requires a new wax pattern.

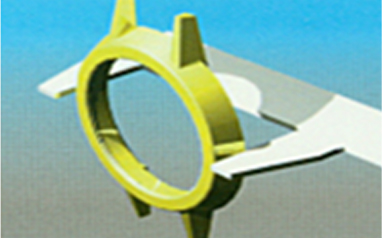

Hot wax is injected into the mold or die and allowed to solidify. Cores may be needed to form any internal features. The resulting wax pattern is an exact replica of the part to be produced. The method is similar to die-casting, but with wax used instead of molten metal.

Hot wax is injected into a mold or die and allowed to solidify, resulting in a wax pattern that is an exact replica of the part to be produced.

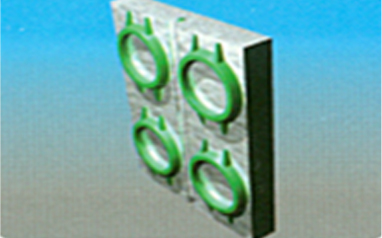

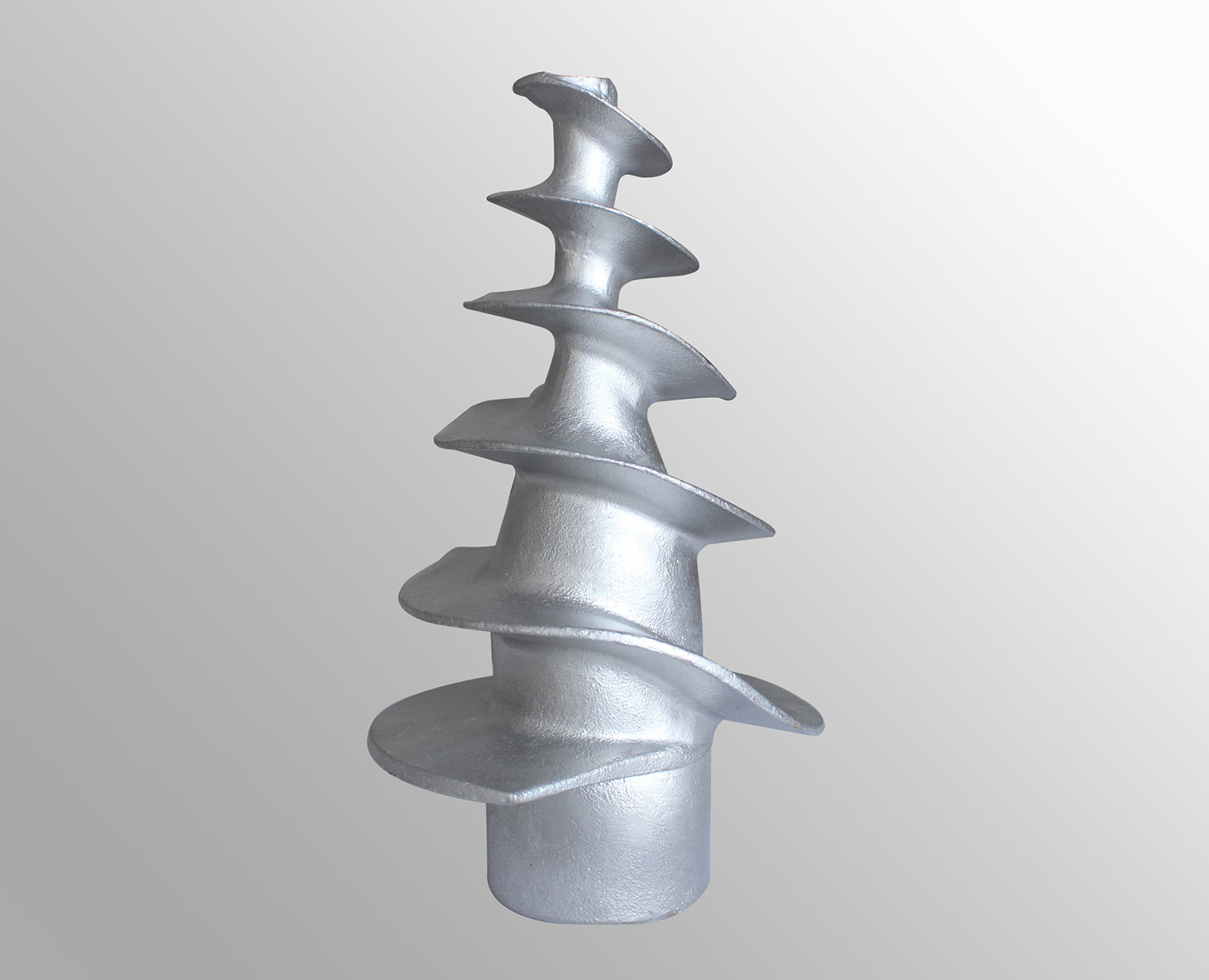

A gating system (sprue, runner bars, and risers) is attached to the wax mold. For smaller castings, several wax patterns are attached to a central wax gating system to form a tree-like assembly. A pouring cup, typically attached to the end of the runner bars, serves to introduce molten metal into the mold.

The assembled “pattern tree” is dipped into a slurry of fine-grained silica. It is dipped repeatedly, being coated with progressively more refractory slurry with each dip. Once the refractory coating reaches the desired thickness, it is allowed to dry and harden; the dried coating forms a ceramic shell around the patterns and gating system.

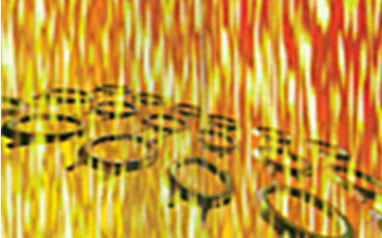

The thickness of the ceramic shell depends of the size and weight of the part being cast, and the pouring temperature of the metal being cast. The average wall thickness is approximately 0.375 in. (9.525 mm). The hardened ceramic mold is turned upside down, placed in an oven, and heated until the wax melts and drains away. The result is a hollow ceramic shell.

The ceramic mold is heated to around 800-900°C. The heating process further strengths the mold, eliminates any leftover wax or contaminants, and evaporates water from the mold material.

Molten metal is poured into the mold while it is still hot – liquid metal flows into the pouring cup, through the central gating system, and into each mold cavity on the tree. The pre-heated mold allows the metal to flow easily through thin, detailed sections. It also creates a casting with improved dimensional accuracy, as the mold and casting will cool and shrink together.

After the mold has been poured, the metal cools and solidifies. The time it takes for a mold to cool into a solid state depends on the material that was cast and the thickness of the casting being made.

Once the casting solidifies, the ceramic molds break down, and the casting can be removed. The ceramic mold is typically broken up by machine. Once removed, the individual castings are separated from their gating system tree using manual impact, sawing, cutting, burning, or by cold breaking with liquid nitrogen.

Finishing operations such as grinding or sandblasting are commonly employed to smooth the part at the gates and remove imperfections. Depending on the metal that the casting was poured from, heat treating may be employed to harden the final part.

Due to its complexity and labor requirements, investment casting is a relatively expensive process – however the benefits often outweigh the cost. Practically any metal can be investment cast. Parts manufactured by investment casting are normally small, but the process can be used effectively for parts weighing 130 lbs or more.

Investment casting is capable of producing complex parts with excellent as-cast surface finishes. Investment castings do not need to have taper built in to remove the components from their molds because the ceramic shells break away from the part upon cooling. This production feature allows castings with 90-degree angles to be designed with no shrinkage allowance built-in, and with no additional machining required to obtain those angles.

The investment casting process creates parts with superior dimensional accuracy; net-shape parts are easily achievable, and finished forms are often produced without secondary machining. Each unique casting run requires a new die to produce wax patterns. Tooling for investment casting can be quite cheap; depending on the complexity, tooling costs can run anywhere between $500 and $1,500.

For high volume orders, the time and labor saved by eliminating or decreasing secondary machining easily makes up for the cost of new tooling. Small casting runs are less likely to make up for the investment. Generally, investment casting is a logical choice for a run of 100 parts or more.

It usually takes 15 days to go from a fresh wax pattern to a complete casting; the majority of that time is taken up by creating and drying the ceramic shell mold. The time and labor-intensive nature of investment casting doesn’t only effect cost, so longer lead times for investment casting are common.

A World-Class Machined Investment Castings Manufacturer

Longxing Casting is a leading and globally recognized brand for complex and high-tech castings in the area of automobile, rail, construction equipment, material handling equipment and agricultural machinery. Steadfast devoting to the field of precision casting and machining for 30 years and with strong engineering capabilities, complete quality assurance system and advanced management system, and deep industry expertise, our world class foundry provides these global industry leaders and medium-to-high end western customers with the highest quality products, services and solutions.

In response to diversified needs of global customers, Qianhao group is established to offer overall solutions and one-stop services. Relying on powerful and matchless machining finish capabilities, our company expand the product lines and is committed to manufacturing and supplying iron and steel castings made by various casting methods, forgings and profile machined parts. Qianhao has developed into a metal parts manufacturer that produce customized components combined various kinds of manufacturing processes. Qianhao group is emerging as a leading metal forming and processing manufacturer that possesses solid comprehensive strength and unique business model.

FOUNDRY OVERVIEW

Utilize advanced lost wax & lost foam & shell moulding casting processes.

Equipped with modern energy saving and environmental friendly production lines.

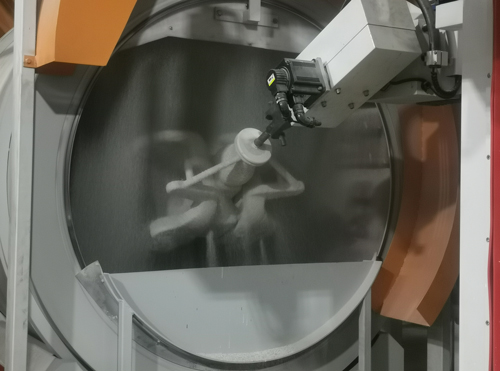

Automatic and semi-automatic wax and shell making, pouring, heat treating equipment.

Our four casting processes

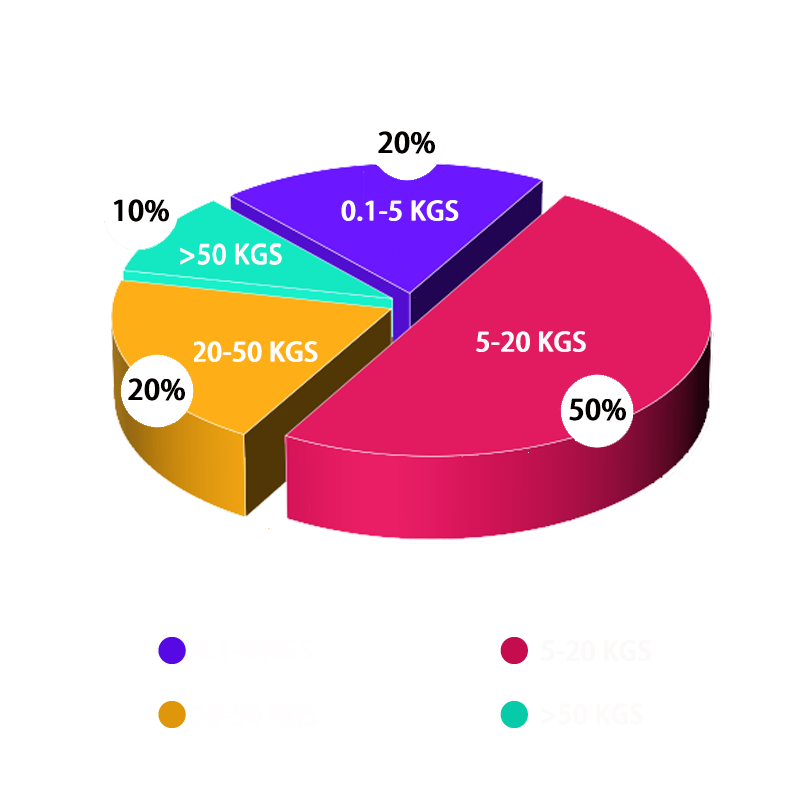

Our four casting processes is able to meet customer's wide range of needs for castings of different grades and qualities.Covering different grades of casting precision (CT6-8),surface roughness (Ra6.4-25um),weight range (0.1-500kgs)

Process Design

Tooling Making

Wax Injection

Wax Patten Assembly

Mold Preheat

Wax Removal

Stuccoing

Dipping

Casting

Mold Shake Out

Work Plece Cut-off

Grinding

Pack & Transport

Final inspection

Machining

Heat Treatment

Tooling

Wax Pattern Making

Wax Pattern Weld Assembly

Wax Tree

Pouring

Shell Roasting

Dewaxing

Automated Shell Making

Heat Treatment

Shot Blast

Inspection

Warehousing

PLC Wax Pattern Machine

Automated Shell Making Line (Water Glass) A

Automated Shell Making Line (Water Glass) B

Automated Shell Making Line(Silica Sol) A

Automated Shell Making Line(Silica Sol)B

Roasting Furnace

Semi-Automatic Pouring

Coreless Medium Frequency Induction Furnace

Shot Blast-Sand Cleaning

Automated Shot Blast

Mesh Belt HT Furnace

Chamber HT Furnace

Hydraulic Press

ISO 9001 & IATF 16949

Ningbo QS.

Ningbo City

Silica Sol Lost Wax Process

Founded 2002

Factory 12,000SM

150Employees

Annual Capacity 4,800tons

High Temp Nickel Alloy, Stainless Steel, Carbon & Alloy Steel

Max linear size - 1000mm Diameter - 600mm

Weight range - 0.01 - 100KGS

Tolerance - CT5 - 6

Surface roughness - Ra 3.2 - 6.3um

Wax Pattern Making

Wax Tree Welding

Shell Making

Shell Dewaxing

Shell Roasting

Smelting&Pouring

Shell Cooling

Shell Smashing

Cutting Gate

Grinding Gate

Shot Blasting

Inspection & Packaging

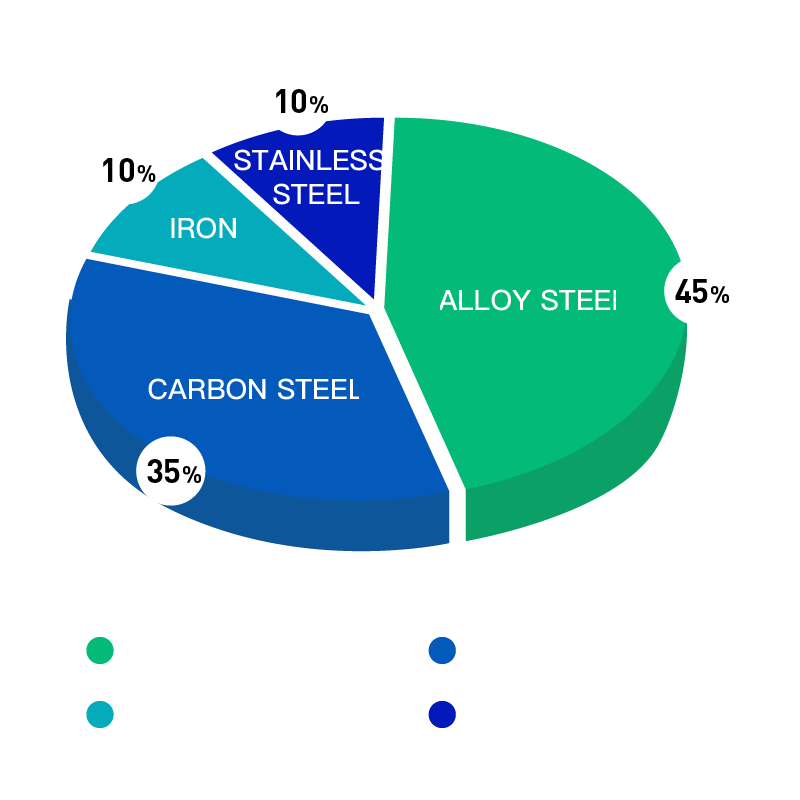

MATERIAL PROFILE

CASTING WEIGHT PROFILE

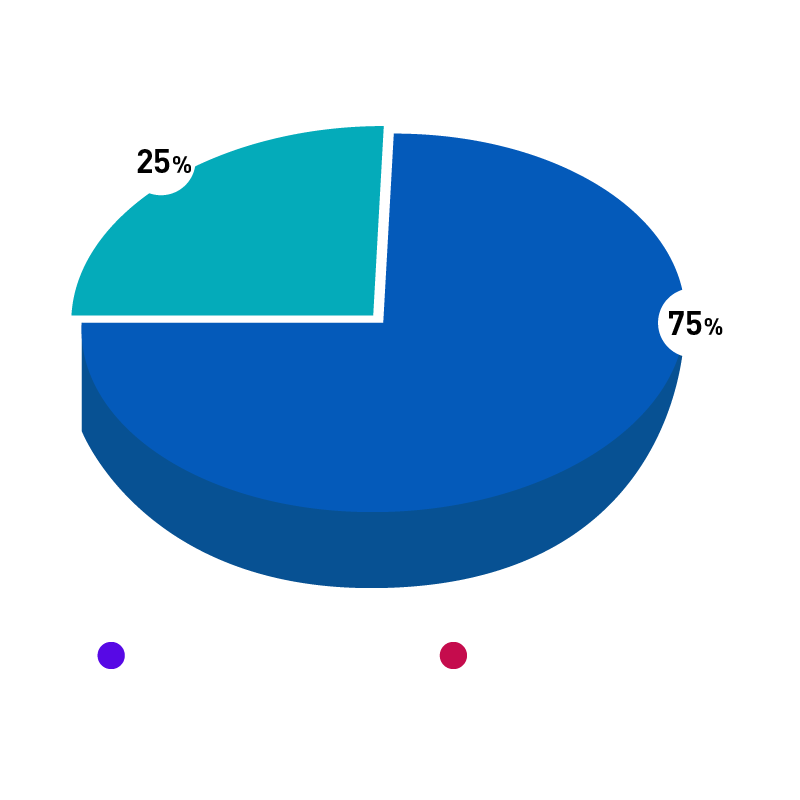

CAPACITY STRUCTURE -LOST WAX INVESTMENT CASTING